FOCUS ON THE FARM

architecture for sustainable food and energy production in Tillamook, OR

Index |

|

|---|---|

The Brief |

Reimagining the economics of industry through architecture and urban design. |

The Problem |

Acknowledging food scarcity and agricultural trends in a county once considered America’s milk jug. |

The Proposal |

New opportunities for an old skillset. |

The Project |

Modular architecture in the form of a biogas digester, aquaponic farm, and pumped storage hydroelectric facilty. |

The Rest |

An appendix of appurtenance. |

When it comes to our industrial processes, our resource utilization and distribution, and everything therein, one meme pretty much says it all, "you’re doing it wrong." So, armed with the ecological systems work of Stewart Brand and H.T. Odum, students focused broadly on the development of architectural typologies with the potential to subvert the existing, growth-oriented economic model, ultimately producing an "Industrial Shed for the 21st Century."3

At 1,600 acres the POTB is the largest full-service industrial park on the Oregon Coast. Formerly designated as Naval Air Station (NAS) Tillamook, the land served as a hangar facility and airport for two blimp squadrons during the Second World War. Today, it’s home to an Air Museum (housed inside one of the original blimp hangars), telecommunications research facility, lumber mill, RV Park, and compost digester (housed in the skeleton of the second blimp hangar) as well as a number of smaller businesses and operations.

Aerial photo of the POTB as it looks today.

NAS Tillmook during construction of Hangar A.

At the time of construction, these were the longest span timber trusses in the world.

Aerial photo of the completed hangars taken after the war.

Interior of the hangar doors, taken during site exploration.

Interior of the hangar walls, taken during site exploration.

Exterior of the Tillamook Air Museum looking North, taken during site exploration.

North edge of the composting digester facility looking East, taken during site exploration.

Exterior of the composting digester facility looking South, taken during site exploration.

East entrance of the composting digester facility looking South, taken during site exploration.

Abandoned saw mill bordering the composting digester facility to the East, taken during site exploration.

Storage facilities on POTB land damaged during a storm in 2007, taken during site exploration.

Entrance to Stimson Lumber yard on the West edge of the composting digester facility looking south, taken during site exploration.

Wetlands adjacent to POTB land, taken during site exploration.

Exterior of the Tillamook Air Museum looking South showing the Stimson Lumber yard to the West, taken during site exploration.

The House That Dairy Built

Oregon's place as the state next to the state next to Canada offered a sense of modest isolation to its residents, especially in the pre-combustion era. Tillamook, then, in the seat of a steep valley on the western slope of the Coastal Range with a single, perilously shallow inlet for harbor ensures a level of geographic isolation once nearly insurmountable. That isolation, and the resultant spoilage of perishable products before they could reach other markets, is the very reason cheese became the county's bread and butter. So, in 1909, roughly a decade-and-a-half after cheese production first came to the Oregon Coast, 10 independent dairy farms banded together to form the Tillamook County Creamery Association (TCCA). Over a one-hundred years later, with nearly one-hundred constituent farms under its flag, that co-op produces a metric mountain of milk-based products stamped with the "Tillamook" brand name and available at a store near you. This story, however, will not focus on how marketing and umami aided lactose in triumph over the human stomach. Instead we'll concern ourselves with what happens when the house that diary built starts to fall apart.

To get a sense of dairy's regional footprint, in 2017,1 the most recent year for USDA Agricultural Census data, milk alone constituted nearly 76% of agricultural commodity sales for the county—$96m of $125m total.2 Crucially, that number represents an 11-point fall for milk as a percent of total commodity sales for the county from the previous Agricultural Census. To drive that drop home, in 2012 the USDA estimated total ag commodity sales for Tillamook at $117m and milk sales at $102m, which is 87% for you math wizards. That decline and the still mammoth milk sales we see today belie a concerning set of trends in community agriculture that have been visible for two decades.

How Farming Bought The Farm

At the beginning of the 20th century, 41% of the US labor force was employed in agriculture, today it's less than 1%. What was once a solid family business with job security, livable wages, and the satisfaction of working with your hands has slowly disintegrated. Consider two representative trends:

The decline in this category truly matters. Small family farms are the communal sweet spot; large enough to meaningfully impact the local economy and food network, and small enough to be independently owned and operated i.e. non-industrialized. Farms of this size often grow for local markets, in contrast to those operating/producing for a national brand, and must do their own processing, packing, and distribution. Because of this, they rely on local businesses not only for their sales, but for supply side inputs as well. They also typically make up the bulk of direct to consumer sales. (In 2017, for example, approximately 15% of farms in Tillamook sold directly to consumers, a number awfully close to the 10% of farms that fell into the category at hand.)5 This feedback loop is far weaker for large farms with commercial backing. The fact that large farms now completely dominate the percent of overall sales for the county, bodes ill for the future of the local economy and the community as a whole.

Dairy farms feel squeeze as much as anyone. Despite cows being almost as revered by Tillamookians as by Hindus, the number of farms with milk cows has plummeted 45%, from 150 in 2002 to 83 in 2017. Milk cow inventory for the county, however, only fell 5% for the same period, implying that large farms subsumed their small and medium counterparts.6

This trend surprises no one. Young people, including young people born and raised in agricultural communities, simply don't intend to sign up for a life of backbreaking labor with a vanishing paycheck. Yeah, duh. Astonishingly though, the problem is worse than it sounds.

Let's say you got a kick out of your 4h years and want to become a farmer in Tillamook. If you enjoy eating and staying alive, and you plan to use conventional techniques, then you require scale. Due to the success of the dairy industry, ag land (inclusive of buildings) in this rural community is valued at $7,796 per acre—about 320% more than the state ag land average of $2,433 per acre.8 A modest, probably-too-small-to-break-even 20-acre property runs you roughly $156,000. Tack on heavy equipment, seeds, feed, chemicals, fertilizer, fuel, construction materials, etc. and suddenly you're staring down the barrel of a very long bill before you begin waking up at sunrise to plow the fields. Considering that even dim-witted bankers might hesitate to throw money at businesses that end in the red more often than not, a lottery ticket and a four-leaf clover are your best hope to get this operation off the ground. Good luck youngblood.

This financial Charybdis helps explain the 16.7% decline in operated farmland in Tillamook, from 39,520 acres in 2002 to 32,936 in 2017.9

If that portrait of doom has you concerned for the farmers, imagine what it means for everyone else.

You Can't Eat Grass

Though cheese was the logical choice during Taft's tenure, don't take that to mean only cows grow in Tillamook. Situated at the confluence of the Kilches, Wilson, Trask, and Tillamook Rivers, annual floodwaters depositing rich, silty soil have created some of the most fertile land in a prolifically fertile state. Add around 90 inches of annual rainfall, cooler average summer temperatures and warmer average winter temperatures relative to the neighboring Willamette Valley, and, voila, a recipe for a slice of the finest non-irrigated cropland in the nation. Do we use nature's bounty to feed the needy? No, we use it to feed cows. Nearly all of county's farmland that isn't occupied by cows is instead occupied by one the state's major cash crops—grass.10 The only problem, people can't eat grass. A situation that makes for the most shocking headline of all:

A 2013 community food assessment survey from the Oregon Food Bank found that 62% of students in Tillamook County were eligible for free or reduced lunch, 32% are living in households considered food insecure, 34% are obese, and nearly 4% are considered homeless. 12 Those numbers would be appalling anywhere in the country, but they are unconscionable coming from a place where everything from apples to zucchinis grows year-round.

Two Final Numbers

Looking through census data for the County, two additional numbers grab your attention. The first, just 22% of residents hold a bachelor's degree or higher, lagging behind the rest of the state by nearly 12%. The second, labor force participation sits at 50%, similarly falling below the state average by about 12%.

Two, admittedly obvious, questions have to be considered before examining this project.

Is it right for the community?

Stating the issues examined above more concisely: Despite or perhaps because of Tillamook's vaunted agricultural heritage, family farms are disappearing leaving gaping holes in employment and local food systems. A project that fails to address that, fails to examine the needs of the community.

Additionally, though the previous section neglected to address the ecological and environmental concerns confronting the Oregon Coast, they are relevant and pressing. Centering the project on a process with the potential to be genuinely sustainable deserves priority.

Farming for The Future

Aquaponics = Aquaculture + Hydroponics. The symbiotic production of vegetables and fish wherein fish eat food and excrete metabolites that are further metabolized by bacteria, the byproducts of which serve as the essential nutrients for plants. Aquaculture systems recirculate water, allowing a large quantity of fish to be raised in relatively small volumes of water by simply pumping the water through filters designed to remove toxic waste products. Nontoxic nutrients and organic matter accumulate in these filters that effectively serve as fertilizer for crops grown hydroponically in the water flowing through the aquaculture the system. In absorbing the dissolved nutrients, the plants further purify the water before it returns to the fish tanks.2

It's fair to question the wisdom of bringing agriculture indoors; requiring active systems to maintain humidity, temperature, and luminance levels, as well as pump and filter water in place where flora thrives outside with energy from the sun water from the sky. Or, it would be fair if commercial agriculture was a simple as tossing a handful of seeds on the ground and praying for rain.

Aquaponics has distinct advantages over conventional agricultural methods. First, water use. Even in an Oregon-Coast-like climate most produce requires irrigation to grow to the supermarket size we've come to expect. Aquaponics systems can exchange as little as 2% of water daily—an amount easily replaced through rainwater capture in this project. Second, fertilizer and pesticides. A well managed aquaponic farm requires negligible nutrient supplementation and no pest deterrents, thereby preventing sketchy chemicals from ending up in the groundwater or nearby rivers. Finally, smaller footprint and greater variety. Crops utilizing hydroponic systems can flourish at densities conventional methods can't imagine, and crop selection is not limited to varieties that can withstand the seasonal fluctuations.3

Relative to conventional farms, though, these operations are energy intensive. As a result, this project includes two facilities designed to improve the sustainable energy infrastructure of Tillamook. To the west, an improved biogas digester with a new solar array will produce sufficient heat and electricity to meet the demands of the farm. To the east, a small-scale pumped storage hydroelectric power plant will help store any excess energy produced from the digester and allow it to be released based on local demand.4

Is it right for the client?

The Port’s current tenants, and so by extension the port itself, have limited integration and interaction with the city and residents of Tillamook. In order to create the thriving locality envisioned by the Port, a successful project will create natural relationships with the businesses and community groups that define Tillamook.

The Project

Modular Design

At the moment, aquaponics is an agricultural niche, and, like most niche hobbies, its prominent apostles are the toolshed-tinkerer types. Google "DIY Aquaponics" and you'll see mostly men, mostly bearded, showing you plastic tubs of every imaginable volume. Though not immediately obvious, this menagerie of containers testifies to the flexibility of this farming method. With a couple thousand bucks and a little extra space, anyone can start growing food.1

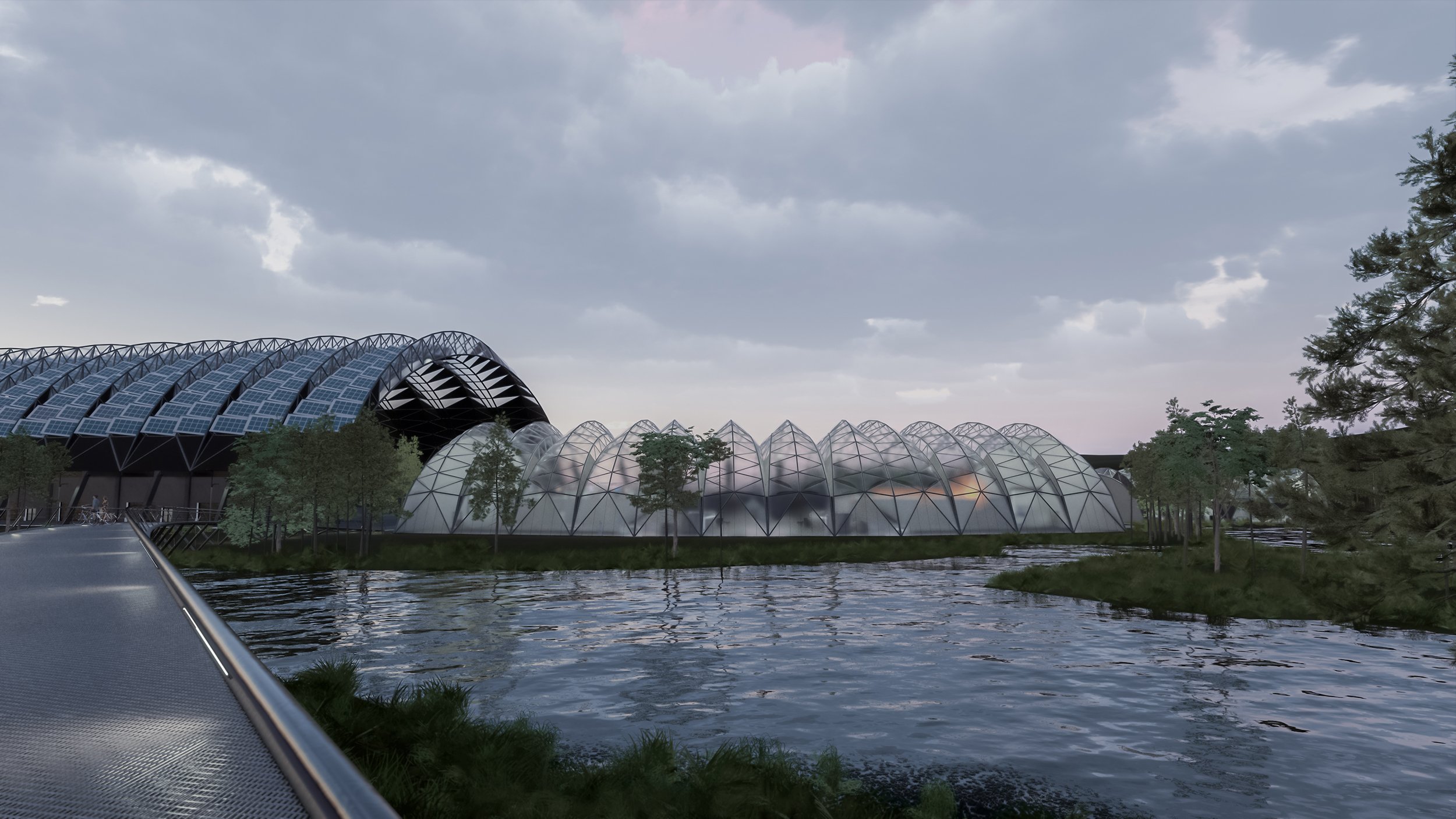

The alternately mesmerizing/nauseating gifs are not suggestions for new loading icons. They are, oddly enough, the genesis of the structural forms used in this project. I embarked on an expansive hunt for inspiration for a modular greenhouse design. Driven by a desire to find a form capable of portability, extendibility, and curvature I took a journey through generative design to Pareto optimization and parameterization that could make a mother worry (and did). See appendix for additional work on greenhouse research and parameterization.

Ultimately, the answer came in the form of an isosceles triangle—a shape that tessellates to allow modular curvature and offers built-in structural advantages. The vertices of the triangles form the attachment points where structure meets earth. To generate stability without additional cross-bracing, each triangle is bisected. These bisectors alternate in height to form a folded plate structure. The following diagram should help clarify the positional relationship between spanning members and the pivot point between modules.

Structure and Skin

Taking cues from both solar greenhouses and hoop houses, the final form has a roughly semicircular profile broken into linear, planar segments of equal length. (The exception being the base members, which are a multiple of that length.) All members are composed of steel pipe with welded connections.2

To allow for flexibility in the reproduction of this system elsewhere, the skin is panelized. All buildings in this project use different ratios of ETFE foils and insulated sandwich panels based on daylight needs. Clamp plates affixed to the top of each structural member by intermediate brackets serve as attachment points for both membrane and opaque panel construction. The folded plate structure generates valleys in the roof line, creating natural places for integral gutters to serve as rainwater collection sites. End walls do not need to be load-bearing, and can be constructed using any reasonable method or material—here depicted as concrete for material consistency.

Biogas Digester & Solar Farm

Power Surge

Moving through the buildings in order from largest to smallest (and west to east), we come first to the revamped biogas digester. The existing digester facility lacks capacity and integration with the rest of the Port and the power grid writ large. This redesign increases capacity, distribution, and storage (for gas and liquid fertilizer) with two, independent digester operations that would be connected to a new power substation. Each of these operations can be subdivided into two independent systems, which could be treated as primary and backup or operated simultaneously to increase output. Heat produced through CHP generators is either re-routed to aid the digestion process or passed to the aquaponic farm.

Additionally, this proposal reconstructs the roof over Hangar A with a nod to the original, funicular form. Slight modifications to the design system accommodates a large solar array along the southern face of the facility.1 Analysis done using the Grasshopper plugin Ladybug, as well as other tools available through NREL, indicate this array could produce 1.271m kWh at a minimum. Penciling out to an average of about 300 kW per hour,2 the energy produced here potentially covers the needs of the aquaponic farm on its own.3 Any excess energy could be used either to the power the digestion process or be stored for later use via the pumped storage hydroelectric facility to the east of the aquaponic farm.

Aquaponic Farm and Research Facility

Education Through Experience

Sitting directly east of the digester facility, the aquaponic farm operates as a functional educational facility. The science of aquaponics poses novel challenges even for experienced farmhands. Those wishing to find success through this method need to know about pH stabilization, nutrient balance (specifically phosphorus), and pest and disease prevention in both aquaculture and hydroponics.1 Overcoming these technical challenges, however, provides farmers with the freedom to grow high value crops, such as basil, that could completely change their financial fortunes.2

A separate vertical farm without daylight access gives researchers the opportunity to explore alternative hydroponic growth methods with a fine level of experimental control. On the second level, an open workspace (west end) allows for a large number of students and researchers to take part in the program while an unoccupied space (east end) allows for future expansion and development.

Pumped Storage Hydroelectic Facility

A Better Battery

The final buildings for this proposal work in conjunction to bolster Tillamook's energy infrastructure—a hydroelectric pumping facility to the east of the aquaponic farm and a headgate-reservoir at the highest point on the site. As far as power stations go the energy stored and produced here is a drop in the bucket, but it could work as a promising test case to bring more pumped storage plants to the PNW.1 An administrative office for the Port would share the pumping facility, hopefully offering a centralized location to meet clients and show off the opportunities of partnering with the Port of Tillamook Bay.

The rise of agriculture and logging industries in Tillamook caused significant environmental degradation to critical riparian habitats.2 In addition to improving the scenic quality of the Port, the constructed wetland that serves as the lower reservoir will ideally offer a new home for displaced wildlife and help rehabilitate an important ecosystem.

Program Development

Early thinking around this project lead to the development of a program where the central building was something more akin to a visitor center. This version included dining, gallery/exhibition spaces, as well as a bunkhouse for the students and researchers. While the scope made sense, it failed to integrate the digester and so lacked a method for sustainable energy generation to power the farm. Nonetheless, the exercise proved useful in the determination of an overall layout.

Greenhouse Research

A truly alarming amount of effort went into creating grasshopper scripts for multi-objective optimization of form using the Octopus plugin to minimize volume and maximize solar radiation. Truly alarming. Sadly, most of that work couldn't be reconciled with the development of a modular form due to conflicting parameters. Also, to be honest, the outcome was nearly indistinguishable from that of a solar greenhouse and was aesthetically uninteresting. (On the upside, the fact that it was nearly indistinguishable from solar greenhouse means the constraints were right.)

Parameterization

This single image does no justice to the focus on parameterization in the creation of this project. I could burry you in scripts. Versions of this project looked at cable tensile forms, others tried glulam lamella structures, and still others used reciprocal frames and they were all made in Grasshopper. Ultimately, however, this is the one that mattered. (Or it's almost the one that mattered because the screenshot was taken before I reached the version labeled, "prototype_final-final-final-final.gh") If the goal was to create architecture that could be tailored to the specific volume and size of anyone anywhere, this stupid mountain of files gets you pretty close. There's even a script that deconstructs the building and lays out the members in neat little rows.

Structural Analysis

If you made it this far, you've read enough. I'm pretty sure all the necessary precautions were taken in releasing members and supports for a satisfactory structural analysis. I'm also pretty sure the damn thing would stand up regardless.